Place of Origin:

China

Brand Name:

Customized

Certification:

Rohs, Reach, UL, CE, ISO

Model Number:

SRK8449

Product Description

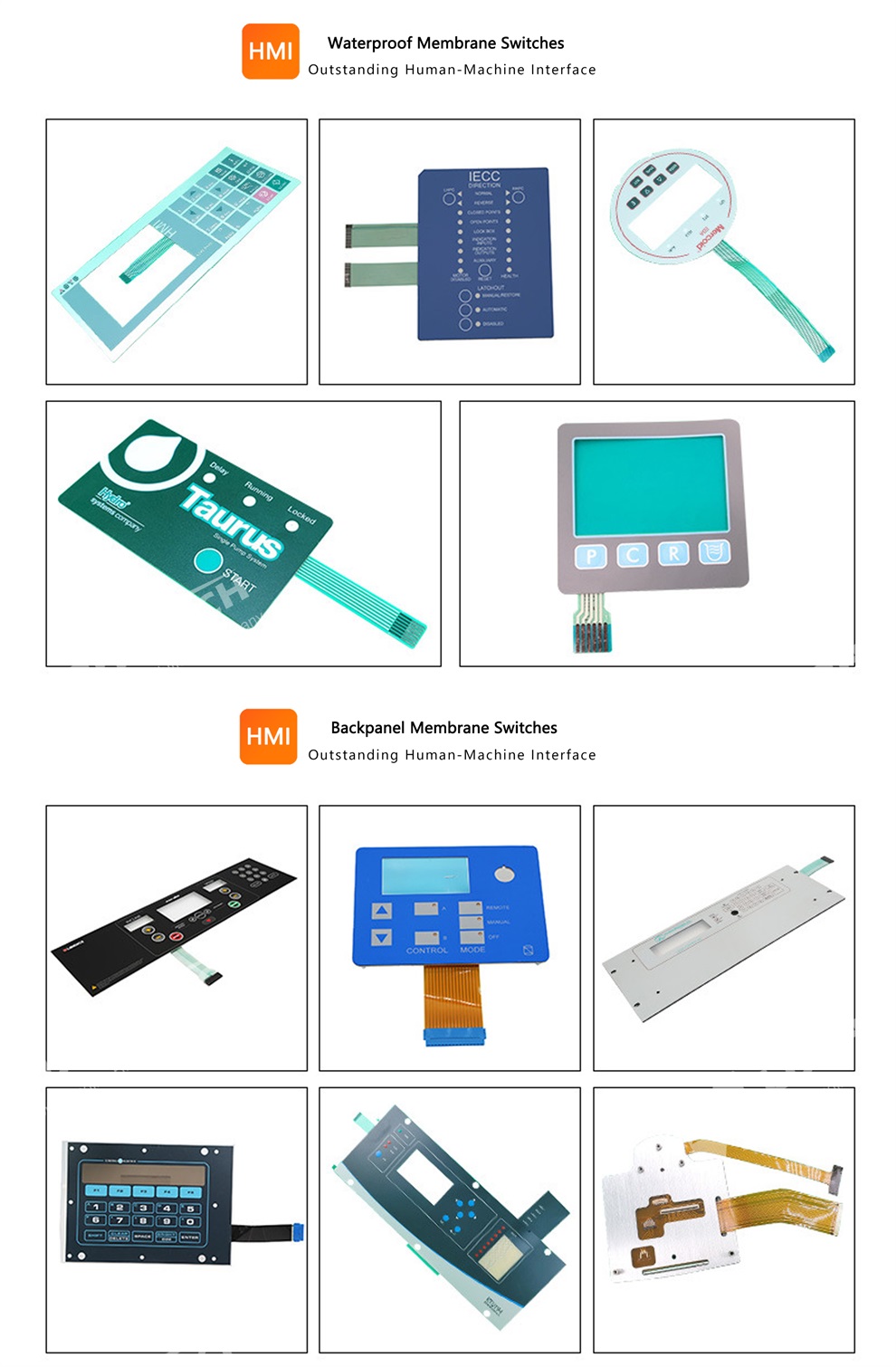

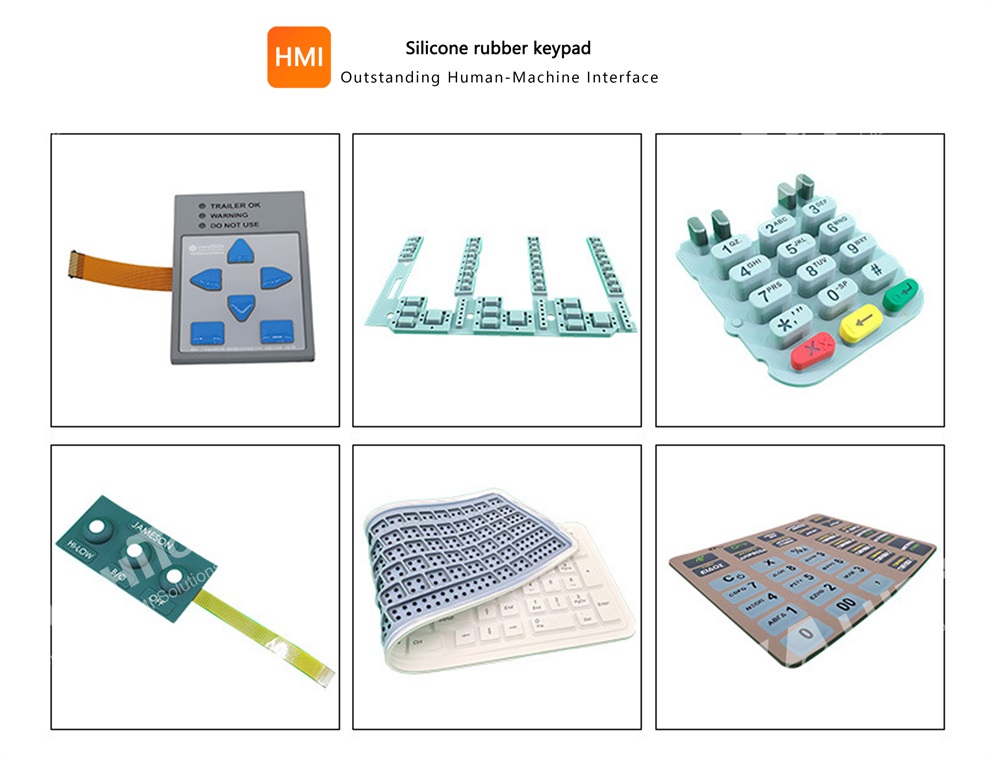

Silicone Rubber Keypad Shore 60A / 70A / 80A Spray And Printed Symbols

Silicone Rubber Keypads / Elastomeric Keypad / Elastomer Keyboards

Silicone rubber keypads are the most widely used form of switch technology today. We offer reliability, long life and design flexibility. Conductive rubber switches and keypads were originally developed for the electronics industry to meet the increasing demand for inexpensive momentary switches. Conductive rubber keypads became desirable because they look and feel like traditional push-button style switches, but do not have their inherent disadvantages.Innovative key coatings for our silicone rubber keypads are silicone, parylene, and Dura (Hard Coat). Silicone rubber keypads can be designed for applications exposed to water and hydrocarbons. Enhanced graphics and lighting options allow your product to incorporate features not found on standard silicone. The silicone rubber keypads are widely used on genset controllers, test instruments, industry production machines etc.

Silicone Rubber Benefits:

Silicone rubber is an excellent choice for device operation controls. It possesses the following characteristics:

? Excellent resistance to both heat and low temperature (-55℃ to 250℃)

? Minimum noise generation due to soft and elastic contact structure

? Minimum abrasion and high resistance to SO2 and oxidation even in heavy humidity

? Design both tactile and linear feedback

? Translucent materials available

? Cost effective

? Multi-color designs easily accommodated

? Water and contamination resistant

> Main Technical Specifications:

| Item | Description | Technical capabilities | ||

| 1 | Max. Size | 1200mm x 1000mm | ||

| 2 | Overlay Material |

PET: Autotype (Autotex F150, F200, F280, V150, V200, V280, Autoflex EBG130, EBG180, EBG250, EBA130, EBA180, EBA250) Autotex : XEV150, XEF200; Autostat CT3, CT4, CT5, CT7 DuPont etc. PC: GE LEXAN--8010 8B35 8B35F HP92S HP40 FR700 FR60 |

||

|

3 |

Spacer | 3M Adhesive, NITTO, TESA, SONY, SEKISUI, Domestic Adhesive | ||

| 4 | Back Adhesive | 3M(Mainly), Others(Little) | ||

| 5 | Silver Paste |

CHANGSUNG: CSP-3163, CSP-3352, CSP-5150; ACHESON: ED 725A(6S-61), ED 427SS, ED 479SS, ED 976SS HV; FUJIKURA and OTTI |

||

|

6 |

Oil Ink | SEIKO, JUJO, DUBUIT, PROELL, NORCOTE UV | ||

| 7 | Carbon Paste | FUJIKURA, ACHESON ED 581SS, OTTI | ||

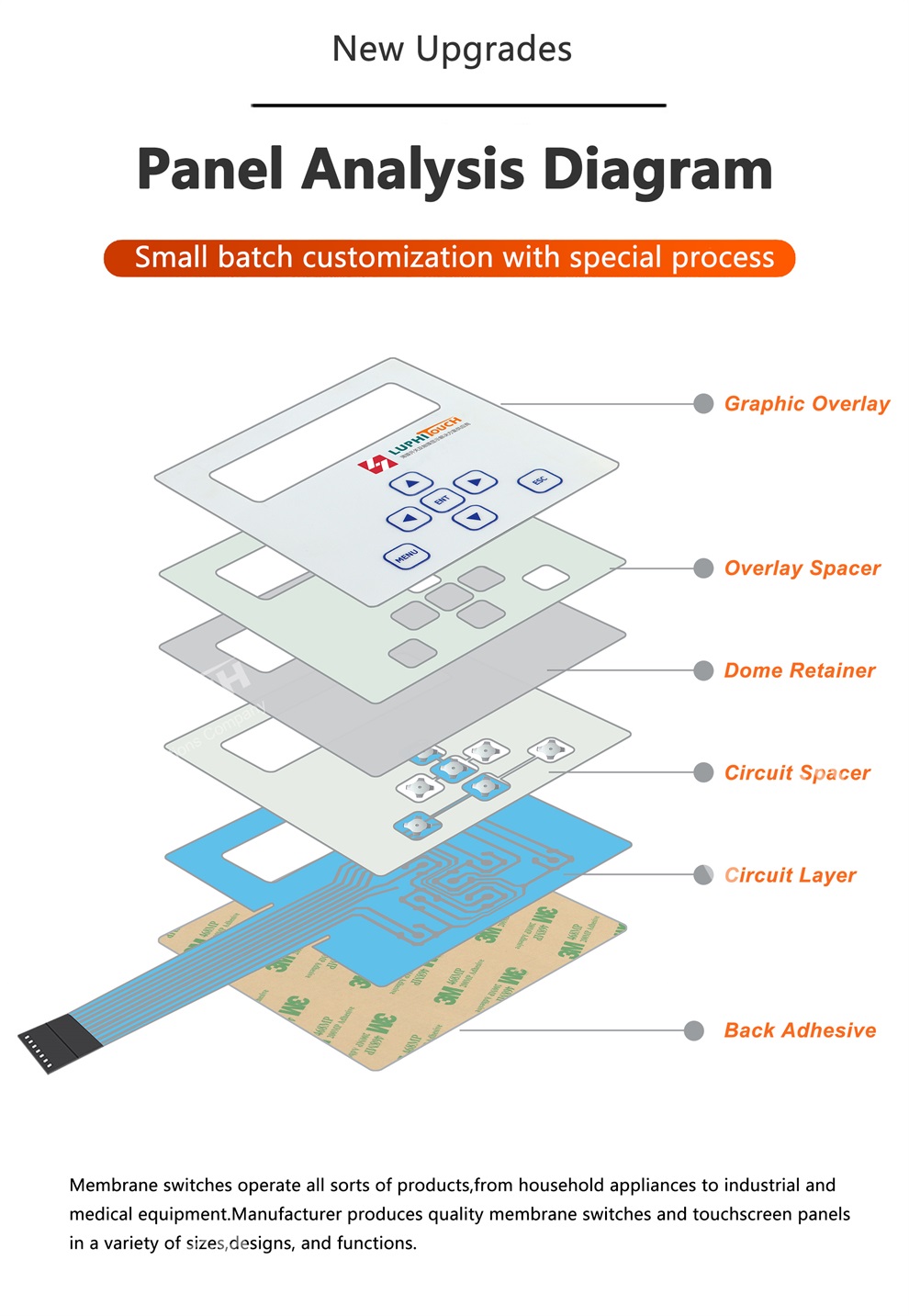

| 8 | 6 Layers Metal dome Type Membrane Switch Structure | Overlay + Spacer + Dome Retainer + Spacer + Circuit Layer+ Back adhesive | ||

| 9 | 4 Layers Polydome Type Membrane Switch Structure | Overlay + Spacer + Circuit + Back adhesive | ||

| 10 | Contact Resistance | 0.5-10Ω | ||

| 11 | Insulation Resistance | ≥10MΩ (100VDC) | ||

| 12 | Base Material Voltage Durable | ≤ 2000V DC | ||

| 13 | Bounce Time | ≤ 5ms | ||

| 14 | Working Current | ≤ 100mA | ||

| 15 | Working Voltage | ≤ 50VDC | ||

| 16 | Life | ≥ 1,000,000 times | ||

| 17 | Key Travel | Flat type: 0.05mm-0.5mm, Tactile Type: 0.1-1.5mm | ||

| 18 | Working Temperature | -40?C-+80?C | ||

| 19 | Actuation Force | 20-550g | ||

| 20 | Storage Condition | Temperature: -40?C~+85?C ,Humidity: ≤98% RH | ||

| 21 | PET Circuit Tail Flexible Feature | 180°to any angle | ||

---FAQ---

> Question 1: What kind of membrane switches we can produce?

Super big size membrane switches, membrane keypads, graphic overlays, membrane circuits, LED backlighting membrane switches, LGF backlighting membrane switches, EL backlighting membrane switches, capacitive membrane switches, rubber keypad membrane switches, FPC circuit membrane switches, PCB circuit membrane switches, metal back panel membrane switches, Acrylic/PC back panel membrane switches,, waterproof membrane switch, anti-UV membrane switch, anti-scratch membrane switch, digital printing membrane switch etc.

> Question 2: What are our main businesses?

Answer: membrane switches, membrane keypads, rubber keypads, nameplates, LCD, touchscreen panels, PCBA, FPCA, Electronics Assembly, Turnkey Project Design and assembly, Total Solution, Components Soursing and assembly, Suncontracting PCBA manufacturing, OEM, ODM etc.

> Question 3: What kind of documents do we need for membrane switch, rubber keypad and PCB assembly?

Answer: Membrane switch: need CorelDraw or Ai or CAD vectograph drawing;

rubber keypads: need 3D drawing for the structure and graphic printing drawing;

Gerber file for PCB or FPC, BOM list, test method;

> Question 4: What is our shipping method?

Answer: for small quantity with low weight, we ship by FedEx, UPS, DHL, TNT express; for big quantity with high weight, we ship by sea or by plane; We also make shipment as per customer's instruction;

> Question 5: What is our payment terms?

Answer: for the new customer, we will do 50% in advance and the rest 50% before the shipment. For long term cooperated customers, we do Monthly Statement;

> Question 6: What is our certification?

Answer: ISO9001:2008;

> Question 7: Can we provide the design service to our customer?

Answer: yes;

> Question 8: Can we provide the material sourcing service? for example sourcing the electronics components, plastic, metal, rubber, wireharness etc. parts for customer's PCBA projects?

Answer: yes;