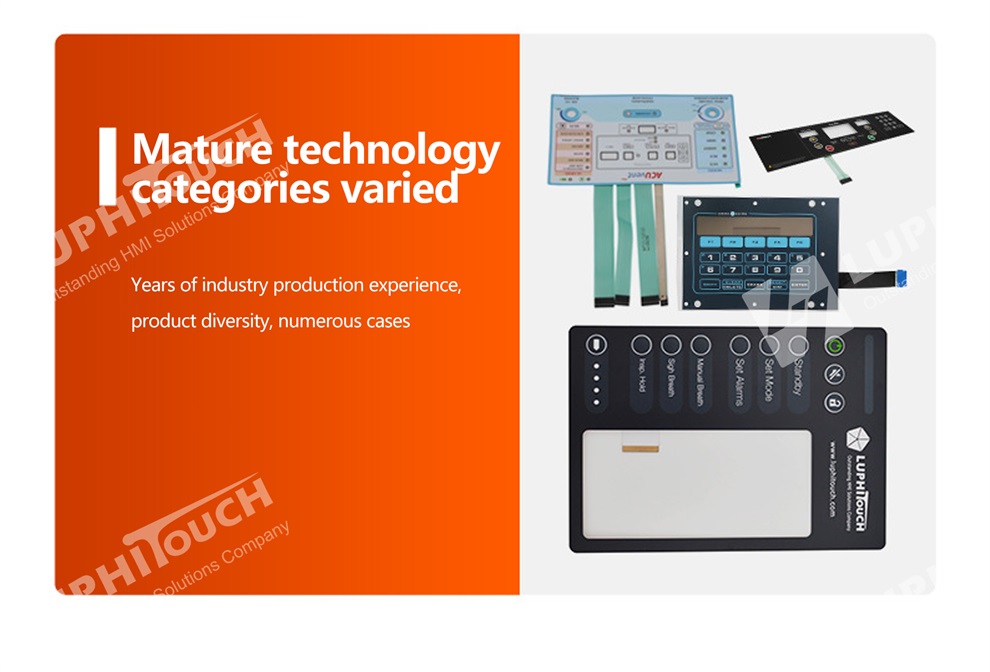

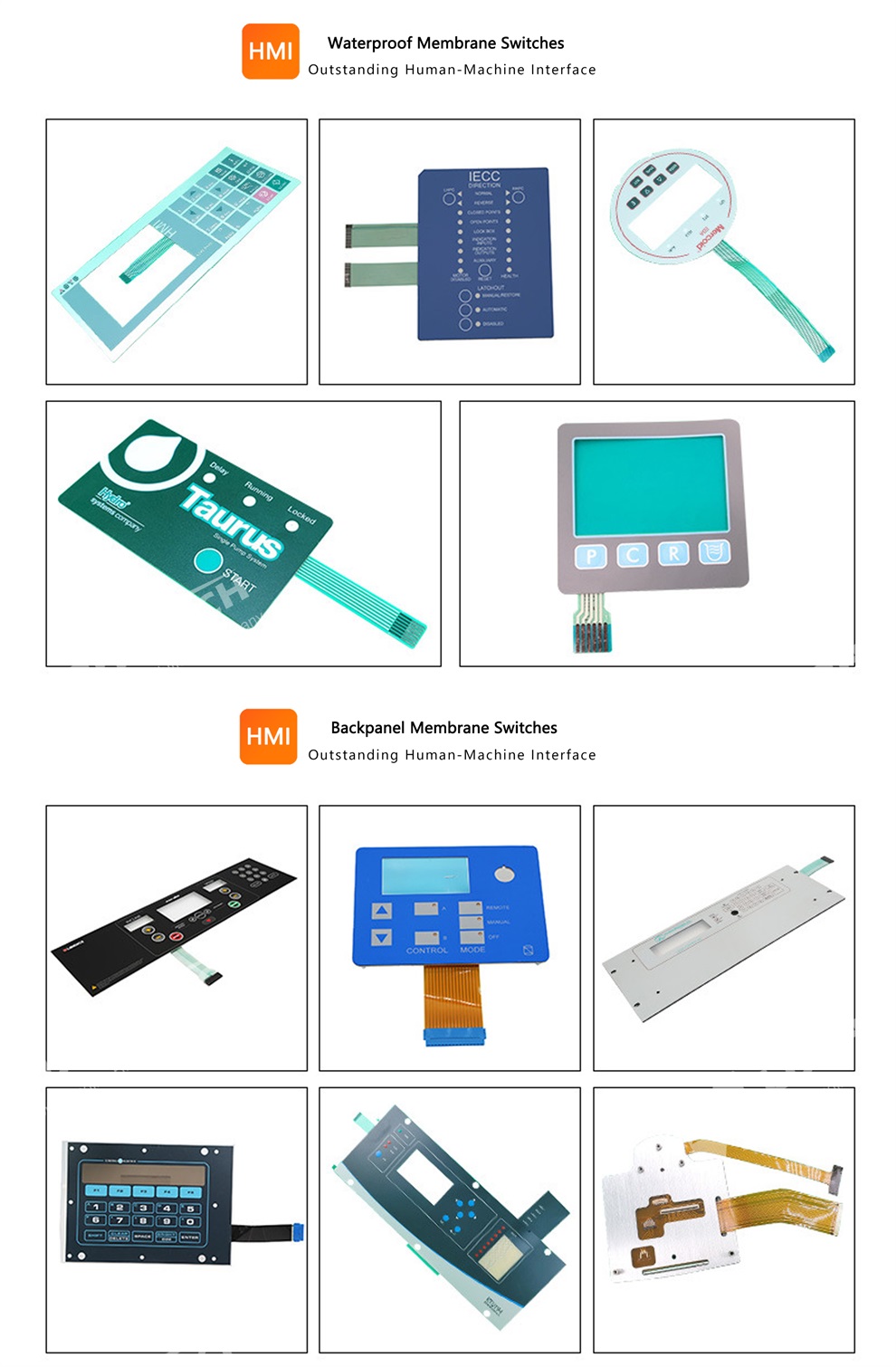

Silicone Rubber Keypads 3M Adhesive

Single Key Silicone Rubber Keypads

Carbon Pills custom rubber keypad

Place of Origin:

China

Brand Name:

LuphiTouch

Certification:

Rohs, Reach, UL, CE, ISO

Model Number:

RS1354

Product Description

Rubber Keypad 3M Adhesive With Carbon Pills

Rubber Keypad Switches with FPC Circuit Spec.:

Single key rubber keypad;Copper FPC circuit layer;1.0mm pitch ZIF connector;Tactile metal dome for button;Rohs and Reach compliance;

| Item | Description | Technical capabilities | ||

| 1 | Max. Size | 1200mm x 1000mm | ||

| 2 | Overlay Material |

PET: Autotype (Autotex F150, F200, F280, V150, V200, V280, Autoflex EBG130, EBG180, EBG250, EBA130, EBA180, EBA250) Autotex : XEV150, XEF200; Autostat CT3, CT4, CT5, CT7 DuPont etc. PC: GE LEXAN--8010 8B35 8B35F HP92S HP40 FR700 FR60 |

||

|

3 |

Spacer | 3M Adhesive, NITTO, TESA, SONY, SEKISUI, Domestic Adhesive | ||

| 4 | Back Adhesive | 3M(Mainly), Others(Little) | ||

| 5 | Silver Paste |

CHANGSUNG: CSP-3163, CSP-3352, CSP-5150; ACHESON: ED 725A(6S-61), ED 427SS, ED 479SS, ED 976SS HV; FUJIKURA and OTTI |

||

|

6 |

Oil Ink | SEIKO, JUJO, DUBUIT, PROELL, NORCOTE UV | ||

| 7 | Carbon Paste | FUJIKURA, ACHESON ED 581SS, OTTI | ||

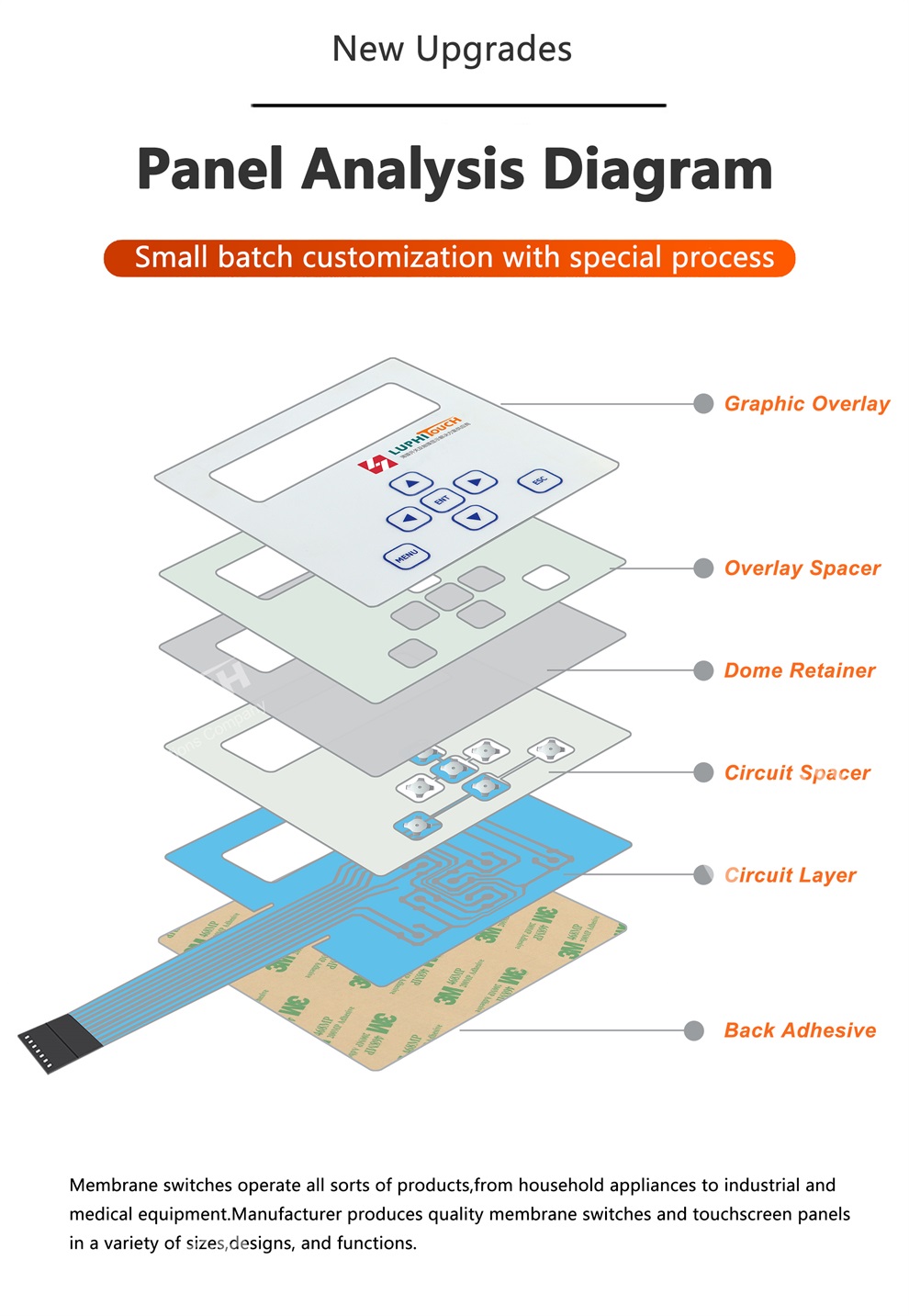

| 8 | 6 Layers Metal dome Type Membrane Switch Structure | Overlay + Spacer + Dome Retainer + Spacer + Circuit Layer+ Back adhesive | ||

| 9 | 4 Layers Polydome Type Membrane Switch Structure | Overlay + Spacer + Circuit + Back adhesive | ||

| 10 | Contact Resistance | 0.5-10Ω | ||

| 11 | Insulation Resistance | ≥10MΩ (100VDC) | ||

| 12 | Base Material Voltage Durable | ≤ 2000V DC | ||

| 13 | Bounce Time | ≤ 5ms | ||

| 14 | Working Current | ≤ 100mA | ||

| 15 | Working Voltage | ≤ 50VDC | ||

| 16 | Life | ≥ 1,000,000 times | ||

| 17 | Key Travel | Flat type: 0.05mm-0.5mm, Tactile Type: 0.1-1.5mm | ||

| 18 | Working Temperature | -40?C-+80?C | ||

| 19 | Actuation Force | 20-550g | ||

| 20 | Storage Condition | Temperature: -40?C~+85?C ,Humidity: ≤98% RH | ||

| 21 | PET Circuit Tail Flexible Feature | 180°to any angle | ||

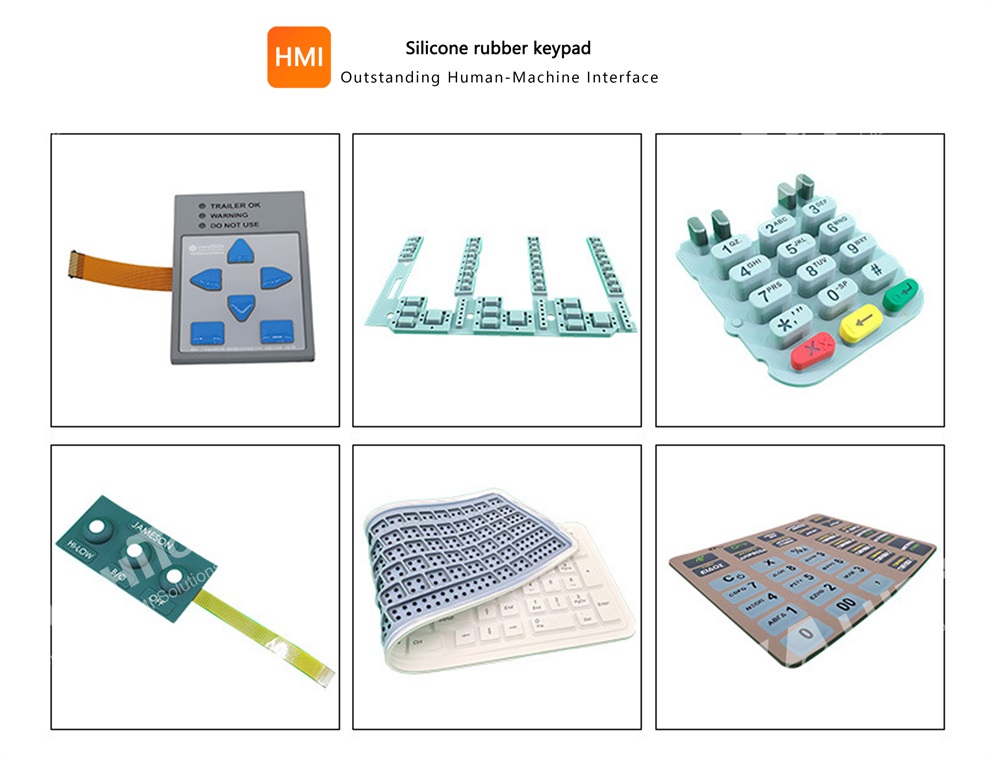

RFQ: How about the standard hardness for the silicone rubber keypad on your rubber switch?

Answer: It is usually 50~65° around;

FAQ: DO you use rubber adhesive for your rubber keypad switches?

Answer: Yes, for rubber sticking side, we use the rubber adhesives like 3M9731-140, DSMS etc.;

FAQ: How to make the rubber keypad switch be waterproof?

Answer: For rubber switch, the best way to make waterproof performance is just design the rubber keypad with border wrapping the circuit packs. Namely make the circuit packs inlayed in the rubber keypad;

FAQ: What is the lead time to make the rubber keypad molding tool?

Answer: It usually needs 14-15 working days. For some complex ones maybe need a little longer.