PRINTED ELECTRONICS

Printed Electronics (Rigid PCB, Flexible FPC with Silver Printed PET Circuit):

Printed electronics is a set of printing methods manufacturers use to create electrical circuit on various substrates. Printing typically uses common printing equipment suitable for defining patterns on material. Such as screen printing, flexography, gravure, offset lithography, and inkjet. By electronic industry standards, these are low-cost processes.

Deposit the Electrically functional electronic or optical inks on the substrate, creating active or passive devices, such as thin film transistors or resistors. Printed electronics are facilitating widespread, very low-cost, low-power applications such as flexible displays.

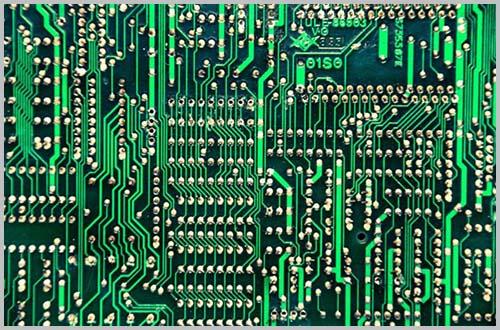

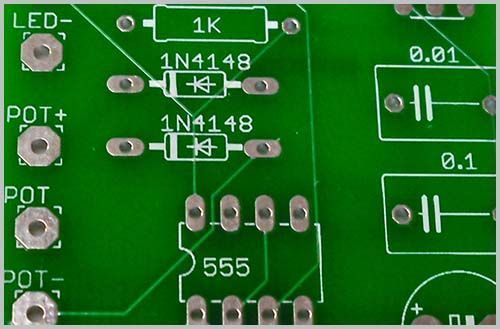

Let us to say Rigid PCB Printing, generally, it is Copper Clad Laminate, with some copper slips embeded on substrate by pressing on temperature, then coating insulation printing. And printing electric components required position with white printing. Marking size, name , parameter of electric components required, thus composed a basic electric circuit board. This kind printed board cost many money , but it can work in high efficiency, conductive property is so good, has a long service time as well.

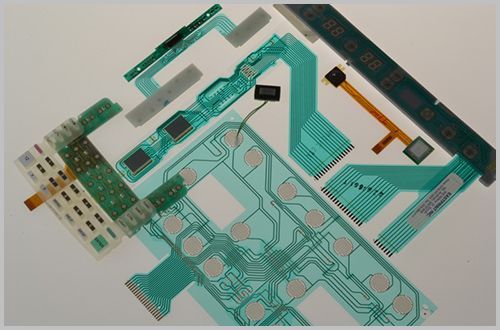

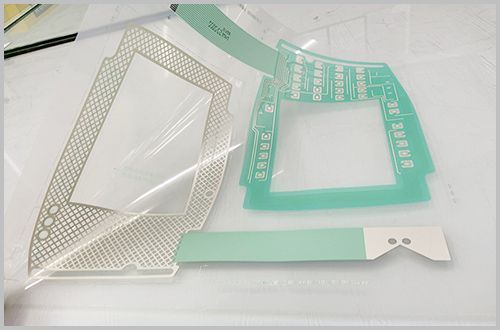

Second one, Flexiable FPC , Fully calling is Flexiable Printed Circuit, it is a piece of PET sheet, on which electronic circuit printed with silver and carbon inks, composed of a basic electric circuit layer. Such printed circuit ‘s cost is lower, it can work normally, conductive property is normal, service time is limited, this kind of FPC printed electronic circuit is used for wearable device widespreadly. Just it is flexiable, is bent , so it can be applied in cloths, glove and sock warming in winter in frozen weather.

The most important benefit of printing is low-cost volume fabrication. The lower cost enables use in more applications. Printing on flexible substrates allows the placement of electronics on curved surfaces, for example, putting solar cells on vehicle roofs. More typically, conventional semiconductors justify their much higher costs by providing much higher performance.

Backlighting Your Printed Electronic Application

If you would like to backlight your application, the construction would incorporate either light guides or LEDs for uniform lighting. Other options for backlighting are fiber optic backlighting and EL backlighting. The backlighting options would vary on the requirements of your application such as thickness preference, shape, environmental exposure, and other unique options. You need to select them so they specifically fit the function of your device. Using the latest LED-powered lighting can reduce cost and reduce the power used by a device. Since many devices today are portable, this backlighting solution is more relevant than ever.

A variety of applications that use backlighting solutions are remote controls, laboratory equipment, and airplane dashboards. In addition, we have medical devices in dimly lit operating rooms, consumer appliances, such as coffee makers and microwaves, laptop keyboards, and many other applications. These applications will come in contact daily or sporadically.

We have various backlighting samples that you can evaluate and consider for your application. Please feel free to submit a sample request and we’ll send you a variety of useful samples and tools you can experiment with for your application.