JOINT DESIGN AND MANUFACTURING

Joint Design and Manufacturing

JDM means joint design and manufacturing which integrates of OEM and ODM service together. For OEM the subcontract manufacturer don’t need strong design capability. On the contrary, they just have very strong manufacturing capability, skilled workers, advanced components supply chain management capability and low price. Then OEM factory can arrange the manufacturing as per customer’s drawings. But ODM is totally different which requires the manufacturer has very strong design capability. But by ODM can waste much time and energy of manufacturer on some uncertain projects and also can make the manufacturer couldn’t gather enough sources to serve well all customers, so JDM owns both OEM and ODM capabilities.

By JDM, it means the enterprise can design and develop a product together. While the supplier can accomplish all design and manufacturing of a project of good idea, along with final box-build assembly. This can create a complex yet rewarding partnership for both the outsourcing material and the project design. It’s a relationship that is built upon collaboration from beginning to end. Of course it contain all joints for design and manufacturing of Electric circuit printed, even to at last box build assembly‘s applicatoins and functions’ testing at all.

Design Electric circuit drawing according to customer’s idea

Confirm Electric circuit drawing and appropriate change for it

Sourcing all required electric components

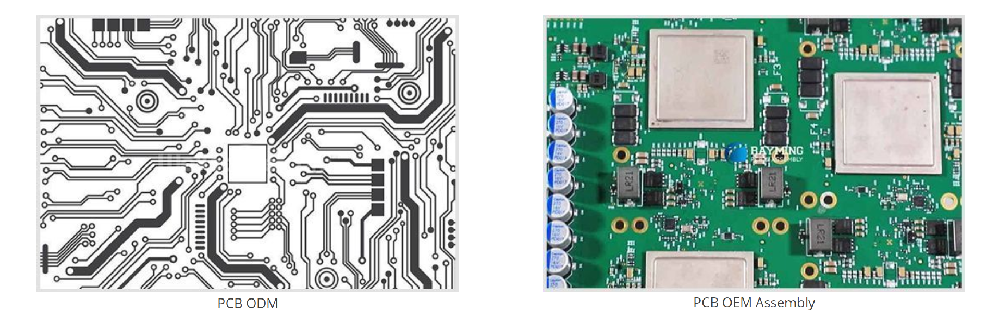

Printing PCB board or Flexiable Printed Circuit

PCB Assembly or Electric Components weld

Come with Membrane Interface or Touch screen Panel

Properties and functions for interface or panel

Check with customer about their running

Hand a complete project to customer in turnkey

When the customer want to design a product, the manufacturer joins in and responsible for designing some parts of this product. Then the customer review manufacturer’s design is workable or not. By JDM the customer and manufacturer can complement each other’s technology weaknesses. The customer can use more less cost to get the final design and even turn key products. While manufacturer also can use more less resources and energy to get the better and more higher profit projects.

Our Joint Design and Manufacturing Services

LuphiTouch’s hardware engineer, electronics design engineer and software engineer can cooperate with our end customer to make joint development for some capacitive front interface enclosure projects and other electronic projects. In the past 10+ years, LuphiTouch always cooperate with our end customers actively to joint designed and manufactured many products.